Advantages :

1. Jet Looms operated on Compressed Air

2. Compressed Air Power Tools

3. Air Feed to Oxygen Generation Plant in Steel Industry

4. Compressed Air Based Blasting, Painting and Powder Coating

5. Oil Removal Downstream of Oil Lubricated Air Compressor

6. Particulate Removal from Compressed Air

Compressed Air Filters are used in compressed airlines to prevent solid and liquid contaminants from going downstream. Compressed Air leaving a Screw or Piston Compressor contains a high water content and oil and other contaminants. It is imperative to employ a Compressed Air Filter to remove these contaminants.DELTA Compressed Air Filters are widely used in the Pneumatic Lines for this purpose. Compressed air typically contains moisture, dust, oil, rust & other contaminants. This necessitates the need for high-efficiency filtration. DELTA Compressed Air Filter uses Pleated Borosilicate Glass fiber-based filter elements. These filter elements have a built-in Pre Filter layer which eliminates the need for a separate pre-filter. The pleated glass fiber media offers a surface area that is equivalent to 5 times the filtration area of competitors’ products. The end result is a low-pressure drop and long life with minimum maintenance costs. We guarantee 10,000 working hours of filter element life.

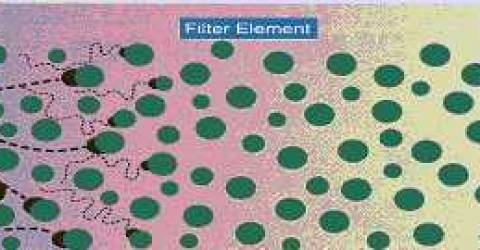

DELTA Compressed Air Filters serve both Particulate and Oil Removal functions. These functions of DELTA Compressed Air Filters are based on three phenomena:

2) Inertial Impaction

3) Brownian Motion

Compressed air filters with coalescing features remove water and oil aerosols by coalescing the aerosols into droplets. This occurs based on the torturous path and pressure drop. Coalescing compressed air filters remove both water and oil mist from the air stream. Further Delta Compressed Air Filters remove particulate contamination through direct interception. Our compressed air filters are rated at 0.01 micron for solid removal and 0.01 mg/m3 residual oil content. This ensures compressed air of the highest purity.

DELTA COMPRESSED AIR FILTER FEATURES DELTA COMPRESSED AIR FILTER FEATURES:

1. Submicron & Coalescing Feature with Oil Removal functionality for Compressed Air

2. Guarantee Technically Oil-Free Compressed Air

3. Compressed Air Filtration down to 0.01-micron particle removal (99.99% efficiency)

4. (0.01 mg/M3) residual oil content in outlet compressed air

5. (1/4" nB through 1" nB) Models in Stainless Steel housings (Lifetime guarantee)

6. Low-pressure drop (0.07 Bar Initial)

7. Long cartridge life

8. Email: sales@deltafilters.com

| MODEL | LINE SIZE (NB) | END CONNECTION | FLOW (nM3/Hr)@ 7 BAR | CARTRIDGE MODEL |

| A-025 | 1/4" | BSP / NPT | 20 | PL24 |

| A-050 | 1/2" | BSP / NPT | 80 | PL48 |

| A-075 | 3/4" | BSP / NPT | 150 | PL415 |

| A-100 | 1" | BSP / NPT | 200 | PL421 |

| S-125 | 1-1/4" | ASA 150 | 400 | PL630 |

| S-150 | 1-1/2" | ASA 150 | 540 | PL645 |

| S-200 | 2" | ASA 150 | 800 | PD830 |

| S-250 | 2 1/2" | ASA 150 | 1000 | PD845 |

| S-300 | 3" | ASA 150 | 1500 | PD860 |

| S-400 | 4" | ASA 150 | 2000 | PD875 |

Larger sizes on request.

| Series | DELTA SS1000 (SS Housings) & CS 1000 (Carbon Steel Housing) |

| Gas Flow Rates (Min / Max) | 1 nM3/ Hr through 20,000 nM3/Hr |

| Gas Operating Pressure | 1 Bar (G)

through 200 Bar (G) 14.5 psig through 2900 psig |

| Line Size | 1/2" nB through 12" nB. Flanged upto 1500 lb Rating |

| Filter Housing MOC | a) Carbon Steel b) SS304 c) SS316 |

| Filter Cartridges MOC | a) Glass Fibre b) Synthetic Fibre c) SS Mesh |

| Filtration Rating | a) 1 micron b) 3 micron c) 5 micron |

| Filtration Efficiency | 98% to 99.999% depending on MOC |

| Pressure Drop | Initial, Clean Condition 0.1 Bar (1.45 psid) , Final 0.7 Bar (10.15 psid) |

Compressed air filters, often referred to as line filters, are used to remove contaminants from compressed air after compression has taken place. Compressed Air leaving a standard screw or piston compressor will generally have a high water content, as well as a high concentration of oil and other contaminants. There are many different types of filters, suitable for different pneumatics applications.

Delta Compressed Air Filters offer the best combination of performance and operating cost. Our compressed air filters guarantee technically oil and particle-free air. With Borosilicate Glassfibre filter cartridges, residual oil content of less than 0.01 (or 0.1, 1, 2) mg/M3 in outlet and particle removal of 0.01(or 0.1, 1, 5) micron are offered. Silicone-treated borosilicate glass fiber media cartridge with in-built pre-filter and final filter layers. Reticulated foam layer for oil drainage tested to ASTM D2986:91. Poly Butylene Terephthalate (PBT) end caps.

COMPRESSED AIR FILTER TYPES:

1. Particulate Air filters: Particulate compressed air filters are used to remove dust and particles from the air.

2. Activated carbon filters: Activated carbon filters utilize a composite carbon material to remove gases and odors from the air. They are used in factories where food is produced or for breathing gas.

3. Coalescing Air Filters: High oil compressed air coalescing filters remove water and oil aerosols by coalescing the aerosols into droplets. This happens partially because of the torturous path and pressure drop. Coalescers remove both water and oil aerosols from the air stream and are rated at particulate contamination through direct interception. Filtration of oil, water aerosols, dust, and dirt particles to 0.01 µm the best achievable in the industry.

4. Cold coalescing Air Filters: Cold coalescing filters are coalescing filters operated at around 35 °F (2 °C), allowing them to be more effective at removing moisture.

DELTA Automatic Condensate Drains for Compressed Air Application:

High reliable Automatic Condensate Drains to drain off the water, oil, condensates from Compressed Air/Gas lines. End connection: 1/2" BSP with manual override at the bottom. The unit is float type and will discharge liquids from the gas stream automatically. Ideal for installation on drain connection of Air Receivers, Filters, Moisture Separators. Sturdy design.No maintenance required. Float Ball Auto Drain, Max Working Pressure: 230 psig, Inlet: 1/2" Male, Outlet: 1/2" Female, Exhaust Capacity: 400L/S, Die-Cast Al. Housing, Stainless Steel inside ball, and hardware

Over 250 Units in Ready Stock

Any Queries: support@deltafilters.com

Copyright © 2021 All Rights Reserved. SEO Optimized by eSearch Logix