DELTA FILTERS & SEPARATORS PVT LTD is an ISO9001:2015 certified company engaged in a wide arena of filtration/separation manufacturing. We are totally focused on delivering Filtration & Separation equipment of the highest grade in quality and reliability. Our company was founded in 1994 by a Research Engineer Mr. M.P.Kini who served in Bhabha Atomic Research Centre (BARC) for over 38 years. Mr. Kini headed Mechanical Maintenance Department for all Research Reactors on site.

Mr. Ajit Kini,

MS Nuclear Eng (Ohio State Univ, USA)

Director (Engineering)

We have handled projects under inspection by the following TPIA

1. Bureau Veritas

2. SGS

3. TUV-NORD

4. TUV-SUD

5. GL-Llyod

6. DNV

7. American Bureau of Shipping

8. Indian Register of Shipping

1. ONGC QAD

2. BARC QA/QC

3. NPCIL QA Dept

4. BPCL QA

5. CQAE (WP)

Testing Services Offered:

1. Radiography of Weld Joints

2. LPT/DPT of Weld Joints

3. Hydro Static Testing of Pressure Vessels

4. Pneumatic Testing of Pressure Vessels

5. Magnetic Particle Testing

6. Ultrasonic Testing

7. Bubble Point Testing for Micron Rating

8. Smoke Test to Determine Air Oil Separation

Mr. Pankaj Rana,

BE Mechanical Eng (Ranchi University)

Senior Project Manager

OIL SMOKE REMOVAL TEST SETUP TO GAUGE COALESCING EFFICIENCY

BUBBLE POINT TEST SETUP FOR MICRON RATING DETERMINATION

FILTER ELEMENT PRESSURE DROP TEST SETUP

HYDROSTATIC TEST OF FILTER WITH CHART RECORDER (PRESSURE VERSUS TEMPERATURE)

ISO 9001:2015 Certificate

Quality Policy

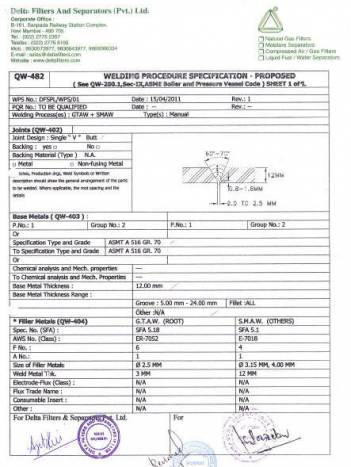

WPS/PQR