Applications:

1. Filtration of Corrosive Gases, Liquids

2. Filtration of Process Steam

3. Purification of High-Temperature Liquids, Gases

4. Catalyst Recovery from Reactors

5. Gas / Liquid Contacting or Sparging; e.g.: Carbonation

Sintered Porous Metal Filter Elements offer many advantages compared to conventional filter elements. Our filters offer media with high strength and uniform porosity with a high degree of precision. The filter elements are manufactured in a range of shapes and sizes.

Filtration rating down to 0.5 microns and up to 100 microns is achieved with high efficiency of 99.9%. Sintered Metal Filters have useful properties. The micron rating is tested in our in-house Bubble Point Testing Facility to validate the filtration rating.

Shapes: Cylinders, Discs, Tubes, Cups

Filtration Rating: 0.5 microns to 100 micron

Efficiency: 99.9%+

MOC: Sintered SS304L, SS316, SS316L, Titanium

DELTA SS316L Sintered Powder Metal Filter Cups with the sample under Bubble Point Test for Micron Rating

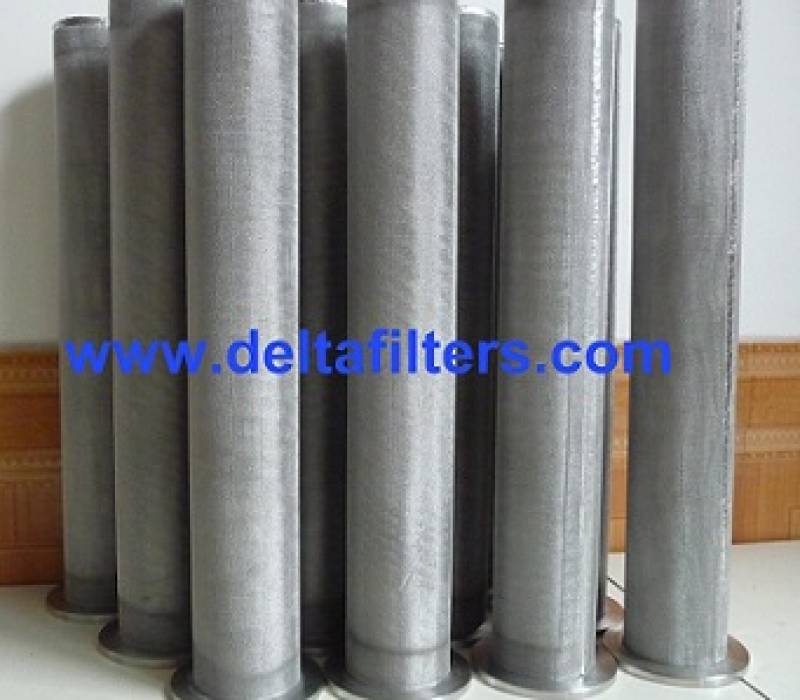

DELTA Sintered Powder Metal Filter Tubes

We also offer Sintered Mesh type filter elements. Compared to traditional mesh-type filters, sintered mesh offers much higher strength. Also, Sintered Mesh can be cleaned repeatedly unlike traditional mesh.

Shapes: Cylinders, Discs, Tubes, Cups

Filtration Rating: 5 microns to 300 micron

Efficiency: 99.9%+

MOC: Sintered SS304L, SS316, SS316L, Titanium

DELTA Sintered Mesh Filter Element and Sintered Mesh Filter Sheet

DELTA Sintered Powder Metal Filter Discs

Any Queries: support@deltafilters.com

Copyright © 2021 All Rights Reserved.